Sustainability and responsible business

Our business is based on using renewable forest materials to create durable products while growing new forests where forests have been harvested as a way of contributing to increasing and prolonging carbon sequestration.

Awareness of our own business activities is more important than ever now that we can see climate challenges beginning to take hold. It is important for us to work sustainably. Beyond our financial goals, we need to be aware of our impact on society and the environment.

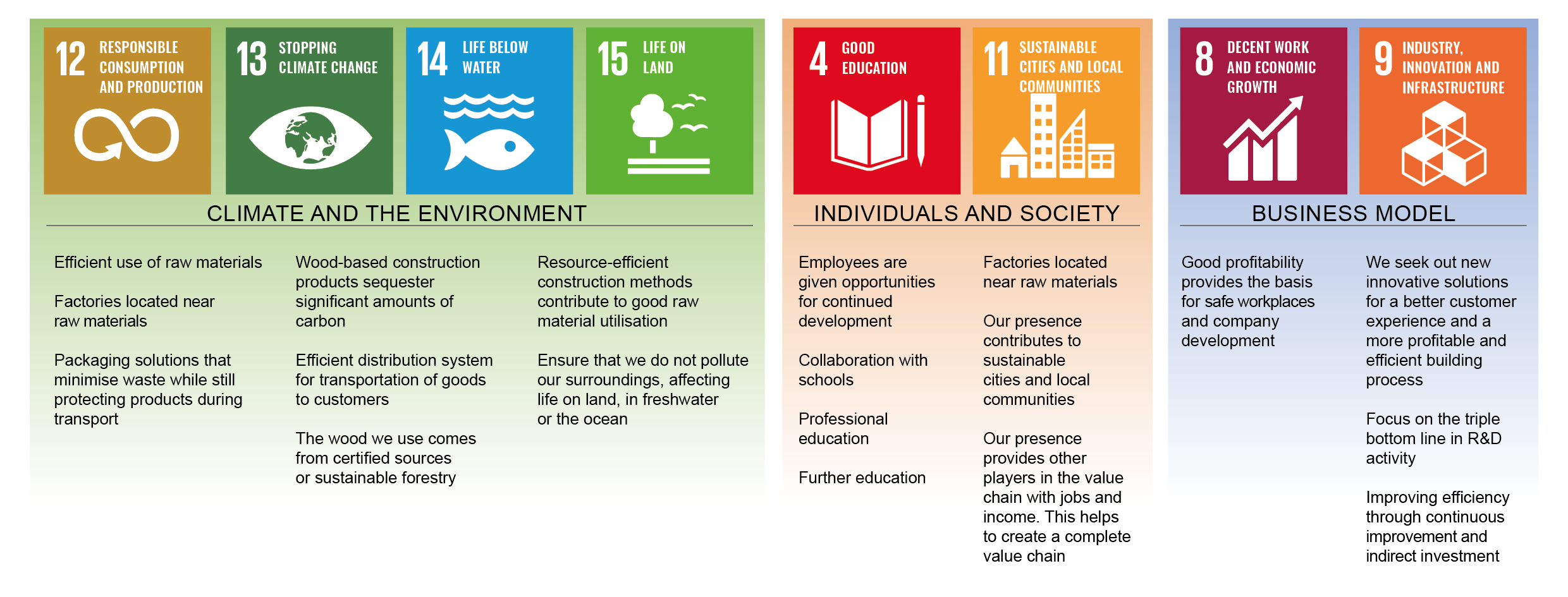

The UN’s Sustainable Development Goals

Carbon sequestration

Certified wood

Future opportunities – returned wood – reusing wood waste

The Norwegian forest and timber industry provides important job opportunities in the local districts. We also make construction products that sequester significant amounts of carbon and keep that carbon sequestered for the entire service life of the building.

Approximately 1 million tonnes of timber from demolitions is sent to Norwegian landfills every year. This is equivalent to about 2 million m³ of wood, which in turn is equivalent to 15% of Norwegian trees harvested. This is a resource that can be recycled into new construction products. We have national targets for material recycling that can only be met by setting up new circular systems in Norway that also include wood. It will take a significant amount of processing to clean timber from demolitions and turn it into new, clean, industrial wood chips. Over the past several years, Forestia has been working on a project where, by investing in new cleaning technologies, we can use wood from demolitions as an input for chipboard production. This will, however, require a major investment of approximately MNOK 250.

As previously described, at Forestia we have developed a project to clean up timber from demolition projects and turn it into industrial-quality wood chips, to make new products from the waste wood. As the project relies on a certain amount of public funding to make it profitable, it is particularly pleasing to see that we have finally seen some success from the apparatus for our project of making wood circular! For further information about Forestia’s sustainability work, please see our sustainability report.